Automatic Power Factor Correction Project Using Arduino | APFC Project

₹8,000.00 Original price was: ₹8,000.00.₹6,500.00Current price is: ₹6,500.00.

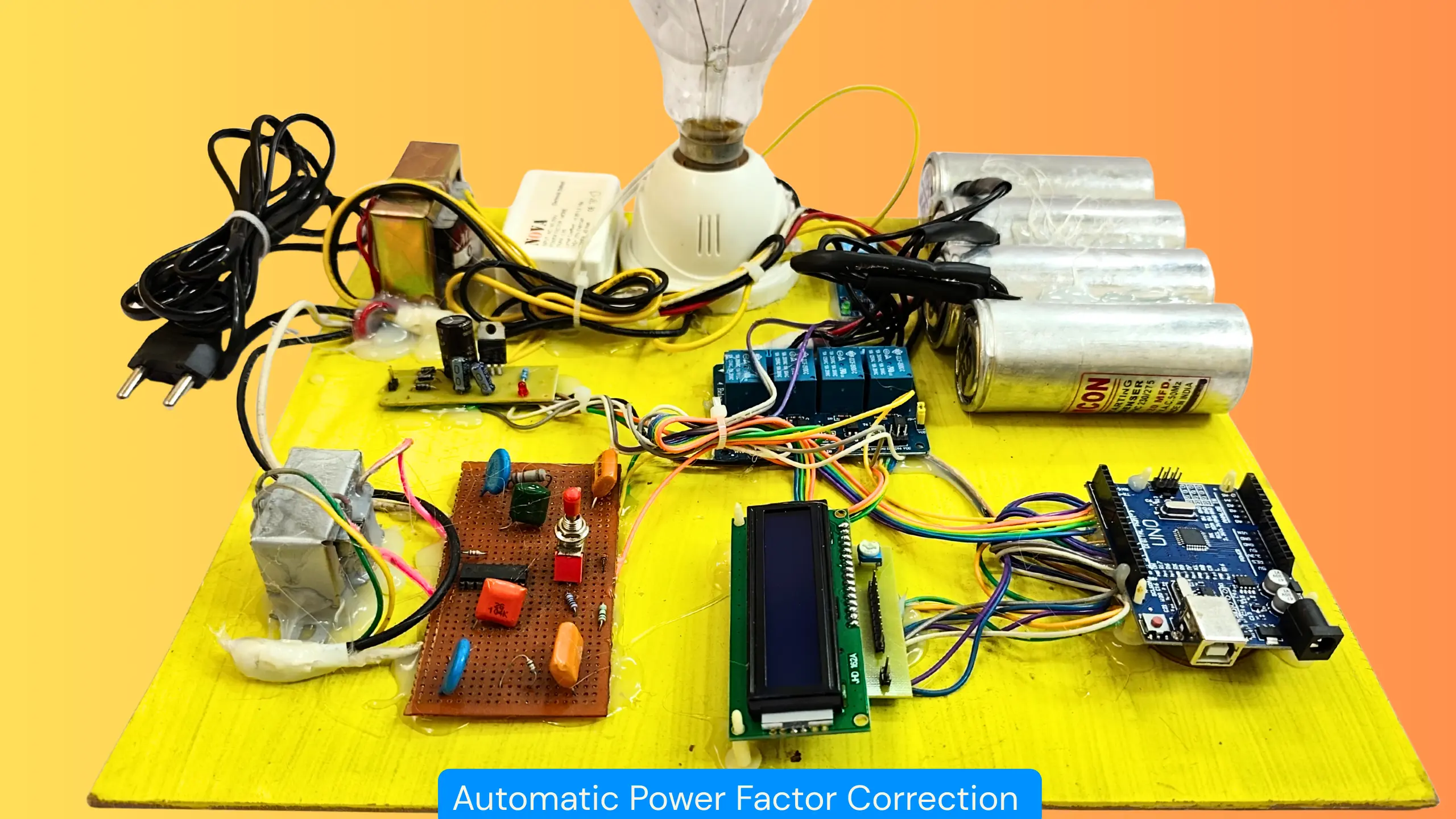

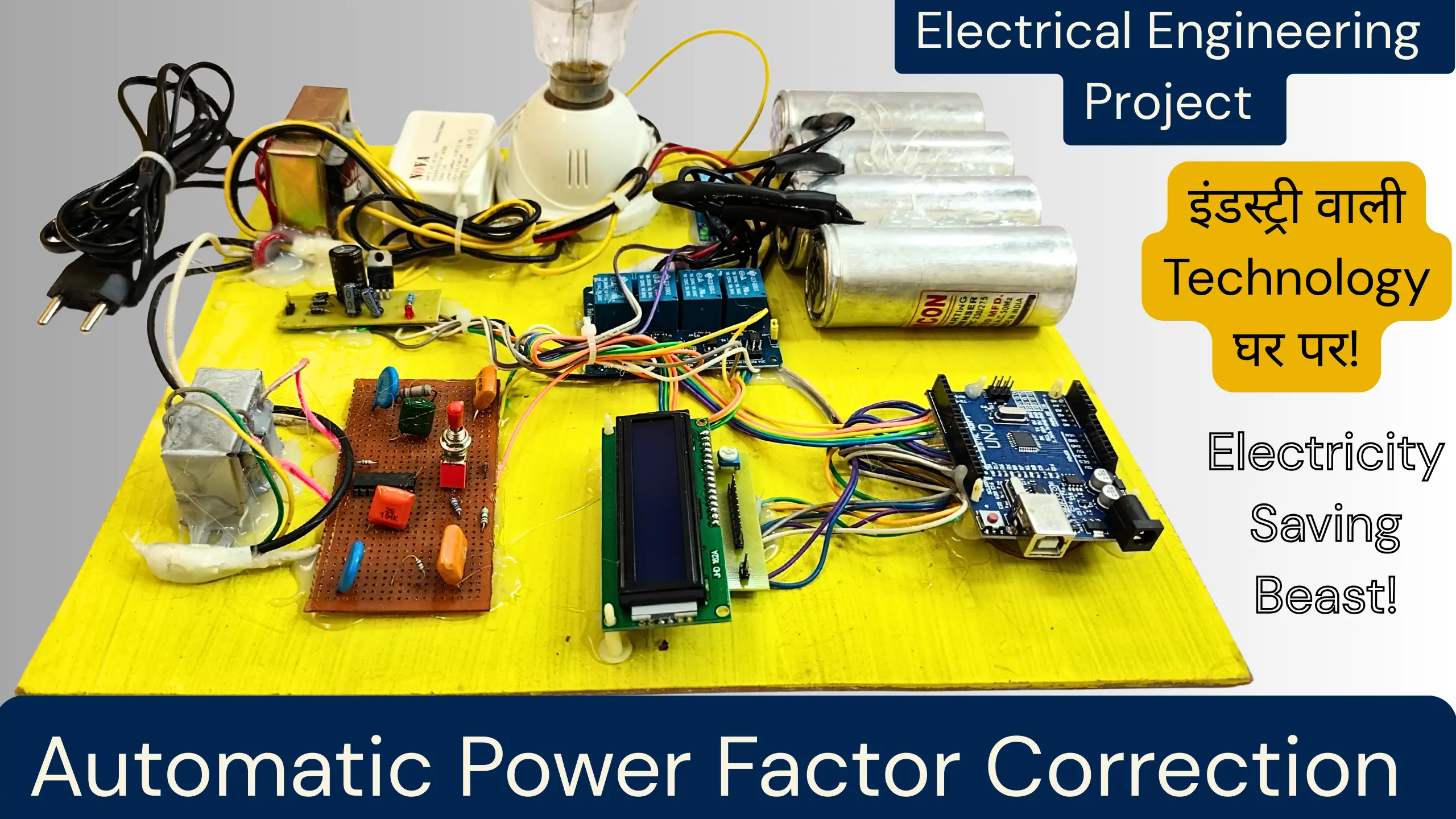

This Automatic Power Factor Correction Project Using Arduino is a ready-made hardware project designed to demonstrate real-time power factor improvement using relay-based capacitor switching ⚡🔌📊. The system intelligently reacts to load conditions and shows the power factor status on LCD, making the concept easy to understand for practical learning 🧠💡.

This project is ideal for Electrical and Electronics Engineering students looking for a final-year project, minor project, or evaluation-ready hardware model 🎓✅🚀. Delivered fully assembled and tested, it helps students confidently explain power factor correction logic during viva, lab exams, and project demonstrations without complex troubleshooting.

96 in stock

Overview

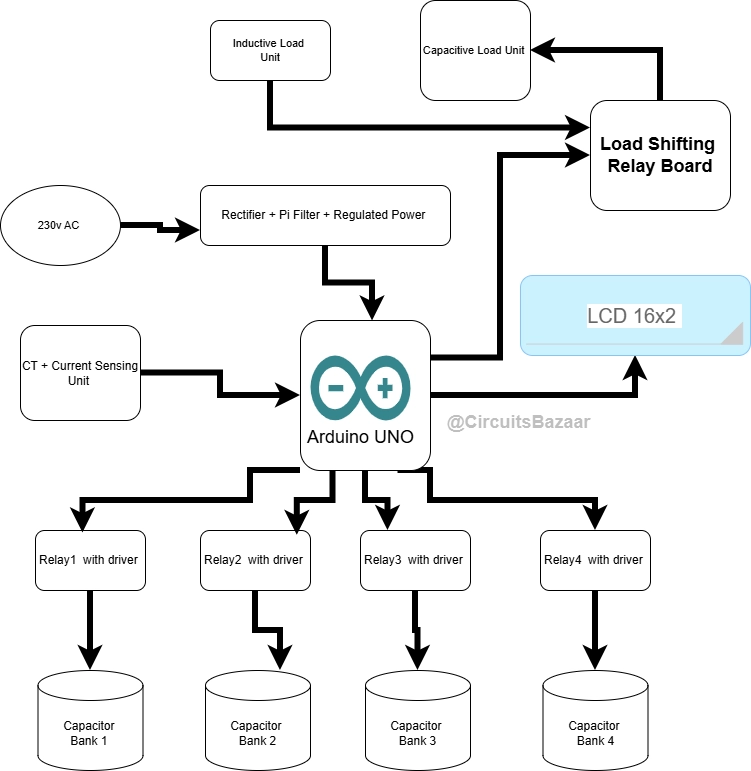

The Automatic Power Factor Correction Project Using Arduino is a practical hardware-based system developed to help students understand how power factor varies with different electrical loads and how it can be improved automatically ⚡. Instead of manual capacitor selection, this project uses relay based power factor correction to simulate how real APFC panels work in industries and substations.

This project focuses on clarity, demonstration, and evaluation readiness rather than heavy theory. Students can visually observe how power factor changes, how capacitors are added step-by-step, and how correction improves system efficiency 📊. It bridges the gap between textbook knowledge and real-world electrical systems, making it highly valuable for academic learning and demonstrations.

What You Will Receive

You will receive a fully assembled and tested hardware project built on an Arduino platform 🧰. The kit includes a complete power factor correction controller setup with relays, capacitor stages, LCD display, and power supply connections.

Along with the hardware, you get structured documentation including a project report, presentation PPT, and synopsis 📄. A full project demonstration video is also provided to help you understand the working flow and confidently explain the project during reviews and viva.

How This Project Helps Students

This engineering hardware project is designed to reduce stress during project submission and evaluation 🎯. Since the system is pre-tested, students can focus on understanding logic rather than fixing wiring or debugging faults.

It improves viva confidence by clearly showing how power factor correction works using automatic capacitor switching. Students can easily explain real-life relevance, system behavior, and outcomes, which positively impacts grading and internal assessment 🧠✅.

Applications & Use Cases

Academically, this project is suitable for electrical engineering final year projects, diploma submissions, lab demonstrations, and technical exhibitions 🏫. It is also useful for explaining industrial concepts like reactive power compensation and energy efficiency.

From an innovation perspective, the project serves as a base model for advanced research, automation studies, and smart power management concepts. It helps students visualize how similar systems are used in factories, commercial buildings, and power distribution panels.

Why Choose This Project

This project saves time and effort because it is ready-to-use and professionally assembled ⏱️. There is no need to source components or worry about circuit reliability.

With clean hardware layout, structured documentation, and guidance support, this project ensures a stress-free submission experience. It is a reliable choice for students who want a practical, presentable, and evaluation-focused project 🚀.

For a detailed explanation of the working principle, control logic, and academic relevance of this implementation, refer to the Technical Guide for the Arduino-based Automatic Power Factor Correction project.

This implementation is part of the Automatic Power Factor Correction (APFC) Project Hub, where multiple controller-based variants are compared across different technologies.

🎥 Project Demonstration Video

Hindi Demonstration 👇

🔗 Internal Resource Links

❓ FAQ

Q1. Is this Automatic Power Factor Correction project suitable for final-year submission?

A. Yes. This project is designed specifically for academic evaluation and final-year submissions. It includes ready hardware, documentation, and demonstration support, making it suitable for BTech, Diploma, ITI, and polytechnic students.

Q2. Do I need advanced programming knowledge to use this project?

A. No. This is a hardware-focused project where the logic is already implemented. Students can understand the working concept without writing or modifying complex code.

Q3. What documentation is provided with the project?

A. You will receive a complete project report, PPT for presentation, and synopsis. These documents help in viva preparation, internal reviews, and formal submission.

Q4. Can this project be used for exhibitions or practical demos?

A. Absolutely. The visible relay operation and LCD output make it ideal for live demonstrations, exhibitions, and lab presentations.

Q5. Will I get support if I face issues during evaluation?

A. Yes. Basic guidance and demonstration resources are provided so students can confidently explain the project logic and operation during evaluation.

| Weight | 3.5 kg |

|---|---|

| Dimensions | 35 × 38 × 11 cm |

Related products

Electrical Engineering Projects

Automatic Wireless Controlled Smart Floor Cleaning Robot – 8051 Based Engineering Project

Electronics Engineering Projects

🔥 Smart Army Robot for Metal & Landmine Detection 🔥 | Army Based Project

Arduino Based Projects

Arduino Based Projects

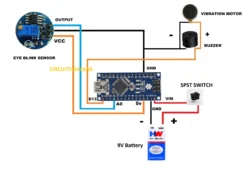

Anti-Sleep Alarm: Eye Blink Detection Project for Drowsiness Prevention #1

Electronics Engineering Projects

Electrical Engineering Projects

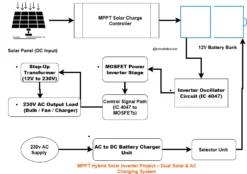

MPPT Hybrid Solar Inverter Project – Dual Solar & AC Charging System

Best Selling Engineering Projects

Solar Inverter Electrical Engineering Project – Buy Ready-Made Model