Electrical Engineering Project Blogs

Four Quadrant Speed Control of dc motor – Ultimate Practical Engineering Project Guide

🧠 Introduction

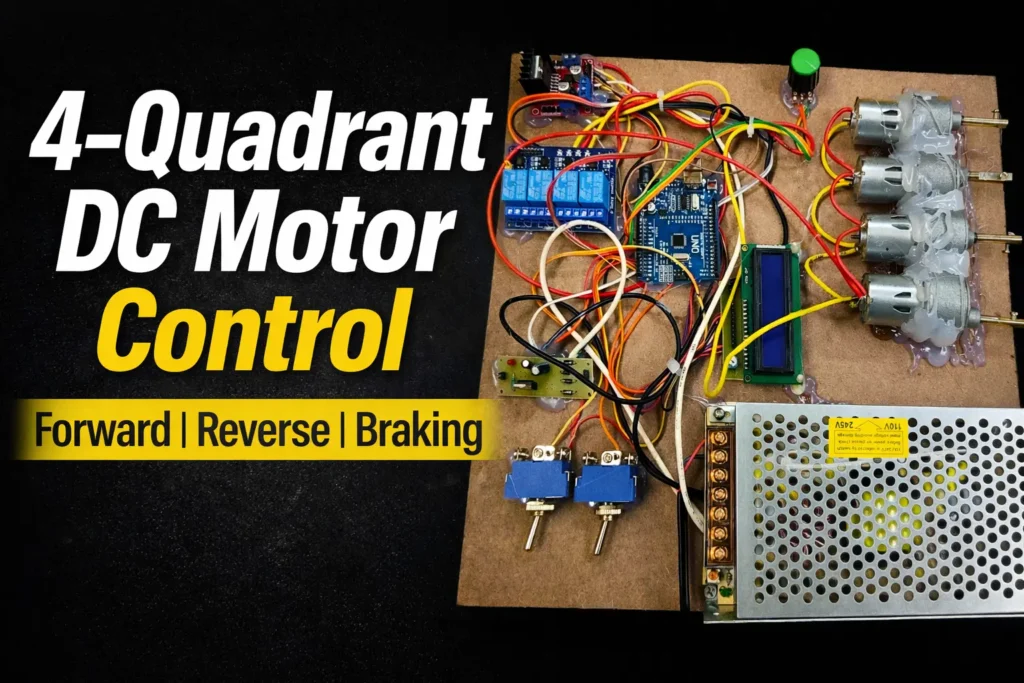

The four quadrant speed control of dc motor is an advanced motor control technique that allows a DC motor to operate in forward direction, reverse direction, and braking modes with controlled speed. 👉 Unlike basic DC motor projects, this system demonstrates how industrial-grade motor drives work in real applications. 💡 For electrical and electronics engineering students, understanding this concept practically is essential for mastering motor drives and automation topics.

Engineering students can download the complete project documentation below. The ZIP file includes a detailed synopsis and a ready-to-use PPT for seminars, viva, and final submission.

Engineering students can download the complete project documentation below. The ZIP file includes a detailed synopsis and a ready-to-use PPT for seminars, viva, and final submission.

⚙️ Project Objective & Overview

The main objective of this project is to design and demonstrate a four quadrant speed control of dc motor system that works with a heavy DC motor. 🎯 This project helps students clearly understand how speed, direction, and braking can be controlled using simple hardware logic.

This project is suitable for:

- Electrical Engineering students

- Electronics Engineering students

- Diploma and Polytechnic students

- ITI and skill-based learners

The system is fully practical and ideal for minor projects, major projects, lab demonstrations, and viva presentations. 👌

🪄 How the Project Works (Step-by-Step Explanation)

The working of the four quadrant speed control of dc motor project can be understood in simple steps:

- 👉 A potentiometer is used as the speed control input. By rotating it, the input voltage changes.

- ⚙️ The controller reads this analog input and generates a control signal to vary the motor speed.

- 📊 A motor driver stage amplifies the low-power control signal to drive a heavy DC motor safely.

- 🔁 Relay logic is used to change motor polarity, allowing forward and reverse rotation.

- 🛑 Braking is achieved by switching the motor terminals in a controlled manner.

- 🧠 The system operates in all four quadrants:

- Forward motoring

- Forward braking

- Reverse motoring

- Reverse braking

This step-by-step operation makes the concept very easy to explain during exams and evaluations.

Basic Wiring Overview

| Pin / Section | Connection | Description |

|---|---|---|

| Potentiometer | Controller input | Speed control |

| Relay Module | Direction logic | Forward / Reverse |

| Motor Driver | DC motor | High current drive |

| Power Supply | All modules | Stable operation |

This clear block-level design helps students understand signal flow easily. 📚

💻 Arduino / Embedded Code

Below is a simplified representation of the embedded logic used in the project:

// Read speed control input

speedValue = analogRead(potPin);

// Generate PWM for speed control

pwmOutput = map(speedValue, 0, 1023, 0, 255);

// Apply PWM to motor driver

analogWrite(motorEnablePin, pwmOutput);

// Relay logic for direction and braking

if (forwardRelay == LOW && reverseRelay == HIGH) {

// Forward motoring

}

else if (forwardRelay == HIGH && reverseRelay == LOW) {

// Reverse motoring

}

else {

// Braking condition

}

🧠 Code Explanation (Simple Terms):

- The potentiometer controls speed by changing PWM duty cycle.

- Relays decide the direction and braking state.

- The motor driver safely handles current for the heavy DC motor.

This logic makes the project easy to customize and extend.

🎥 Project Demonstration Video

🎬 Hindi Demonstration 👇

📦 Related Product Link

👉 Buy Fully Assembled Four Quadrant Speed Control of DC Motor Project from Circuits Bazaar🧩 Components Used

| Component | Short Description | Function |

|---|---|---|

| DC Motor | Heavy-duty DC motor | Mechanical output |

| Motor Driver | High-current driver | Power amplification |

| Relay Module | Electromagnetic switching | Direction & braking |

| Potentiometer | Variable resistor | Speed control |

| Controller | Embedded control unit | Logic & processing |

| Power Supply | Regulated source | Stable voltage |

📈 Applications

- Electric vehicle drive systems 🚗

- Industrial conveyor systems

- Elevators and hoists

- Robotics and automation platforms

- Machine tools and motion control

🌱 Advantages

- Complete speed and direction control

- Demonstrates real industrial motor drive behavior

- Easy to understand and explain in viva

- Suitable for academic and practical learning

- Expandable for advanced features

⚠️ Limitations

- Slightly higher complexity than basic motor projects

- Requires proper power handling for heavy motors

- Relay-based braking is not regenerative

🚀 Future Scope & Enhancements

This four quadrant speed control of dc motor project can be enhanced further by:

- Adding regenerative braking concepts 🔮

- Implementing closed-loop speed control

- Integrating IoT-based monitoring 🌐

- Using industrial motor drive controllers

Such upgrades make the project suitable for research and advanced applications.

🔗 Internal Resource Links

🌐 External Reference

📚 References / Further Reading

❓ Frequently Asked Questions

❓ What is four quadrant speed control of DC motor and why is it important?

A. The four quadrant speed control of dc motor allows a DC motor to operate in forward direction, reverse direction, and braking modes with controlled speed. 💡 This concept is important because it represents how industrial motor drives work in electric vehicles, cranes, elevators, and automation systems. Understanding it helps students move beyond basic motor control and learn real-world drive systems.

❓ How does braking work in the four quadrant DC motor project?

A. In this four quadrant speed control of dc motor project, braking is achieved by changing the motor terminal connections using relay logic. ⚙️ When braking is applied, the motor slows down safely instead of stopping abruptly. This controlled braking improves safety and demonstrates industrial motor behavior clearly.

❓ Is this project suitable for major or minor engineering projects?

A. Yes, this project is highly suitable for minor projects, major projects, and final-year submissions. 📘 It covers advanced topics like speed control, direction control, and braking, which are highly valued during viva and project evaluations. The ready-made hardware and documentation make it easy to present and explain.

❓ Can this four quadrant DC motor project be modified or upgraded?

A. Absolutely. 🚀 Students can enhance the four quadrant speed control of dc motor project by adding regenerative braking, closed-loop speed control, IoT-based monitoring, or current sensors. These upgrades help students explore research-level and industry-oriented applications.

❓ What level of students can easily understand and use this project?

A. This project is suitable for Diploma, Polytechnic, B.Tech, M.Tech, ITI students, and hobbyists. 🧠 Even beginners can understand it because the working principle is explained step by step, while advanced learners can use it as a base for further innovation.