Electrical Engineering Project Blogs

Automatic Power Factor Correction (APFC) Projects: A Comparative Guide Across Technologies

Introduction

Automatic Power Factor Correction (APFC) projects are a fundamental part of electrical and power engineering education, bridging the gap between theoretical power system concepts and real-world industrial implementation. These projects are widely used as APFC projects for students across diploma, undergraduate, postgraduate, and research-level programs due to their strong academic relevance and practical importance.

An automatic power factor correction project focuses on maintaining the power factor of an electrical system close to unity by continuously monitoring system parameters and applying corrective action automatically. What makes this project family unique is that the same power factor correction engineering project can be implemented using different control technologies, each offering a distinct learning experience. This hub is designed to explain the common concept once and present multiple APFC controller implementations in a structured, comparison-friendly manner.

Core System Overview

In electrical power systems, inductive loads such as motors, pumps, compressors, and transformers introduce reactive power, which causes the power factor to deteriorate. A low power factor increases line current, leads to higher losses, reduces system efficiency, and often attracts penalties from utility providers. Addressing this issue is a critical requirement in modern power installations.

An automatic power factor correction controller works by continuously sensing voltage and current, calculating the phase difference between them, and determining the system power factor. Based on this evaluation, the controller automatically switches capacitor banks to compensate for reactive power. This automatic power factor improvement system operates as a closed-loop control mechanism, ensuring efficient energy utilization, improved power quality, and compliance with electrical standards in industrial and commercial environments.

Common Capabilities Across All APFC Project Variants

- Practical demonstration of power factor correction techniques used in real installations

- Real-time monitoring of voltage and current parameters

- Continuous calculation of power factor in an operating system

- Automatic switching of capacitor banks for reactive power compensation

- Closed-loop control without the need for manual intervention

- Reduction of reactive power losses and improved energy efficiency

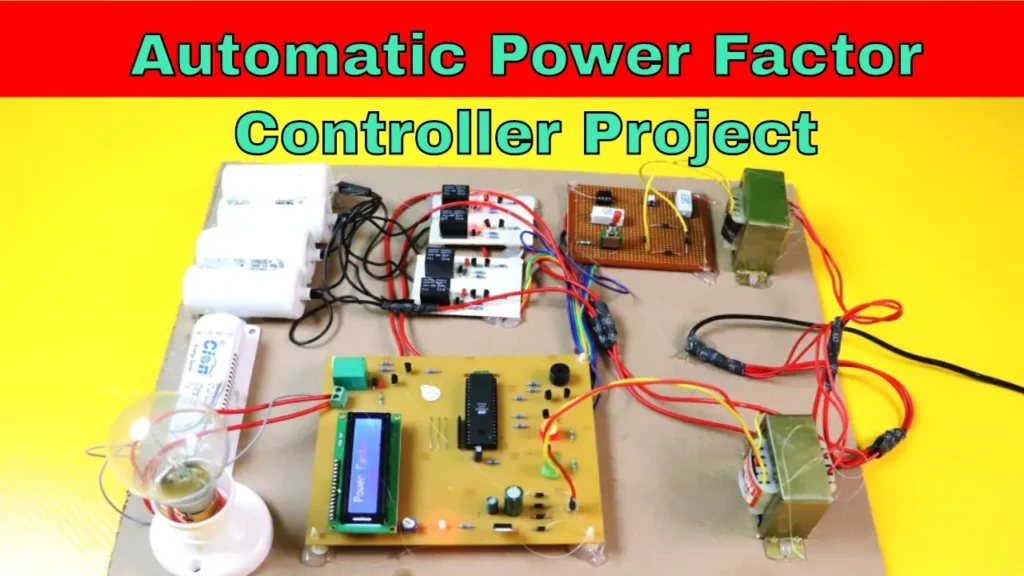

8051 Microcontroller-Based Automatic Power Factor Correction (APFC) Project

This automatic power factor correction controller variant is built around the classical 8051 microcontroller architecture, offering a deterministic and low-level approach to power factor correction. It reflects traditional embedded system design methodologies commonly encountered in industrial and legacy control environments.

This implementation is best suited for learners seeking deeper exposure to timing logic, register-level control, and foundational embedded concepts within a structured power factor correction techniques learning model.

Key Differentiators

- Register-level control providing strong embedded system fundamentals

- Deterministic timing behavior suitable for industrial-style control logic

- Closer alignment with classical and legacy automation systems

- Ideal for understanding low-level power factor correction engineering project design

- Commonly selected as an APFC project for students in diploma and core electronics programs

This 8051 microcontroller-based Automatic Power Factor Correction (APFC) project follows a classical embedded systems approach, making it suitable for learners who want deeper exposure to register-level control and deterministic timing behavior. A detailed explanation of the working principle and control methodology is available in the Technical Guide, while the fully assembled Ready-Made Project Kit allows students to directly implement and demonstrate the system in labs or evaluations.

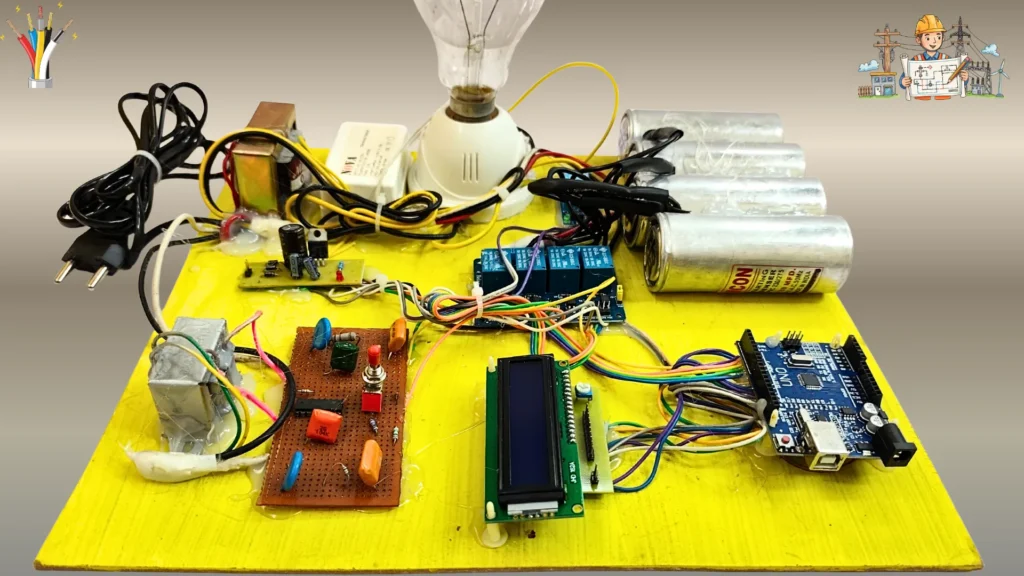

Arduino-Based Automatic Power Factor Correction (APFC) Project

This automatic power factor correction project is implemented using a programmable Arduino platform to achieve real-time monitoring and correction of power factor. The architecture emphasizes readable control logic and flexible system behavior, making the APFC controller easier to analyze, modify, and extend for academic learning.

This variant is especially suitable for learners who want strong conceptual clarity, rapid prototyping capability, and exposure to modern implementation practices within a power factor correction engineering project framework.

Key Differentiators

- Software-driven control logic ideal for conceptual understanding and experimentation

- Easier adjustment of correction thresholds and timing parameters

- Strong compatibility with academic labs and project-based curricula

- High flexibility for extending into an automatic power factor improvement system

- Widely adopted as an APFC project for students in contemporary engineering programs

This Arduino-based Automatic Power Factor Correction (APFC) project demonstrates how programmable controllers can be used to measure power factor in real time and automatically apply reactive power compensation. Learners interested in understanding the control logic, timing strategy, and implementation flow can refer to the dedicated Technical Guide, while those looking to directly implement the solution can choose the Ready-Made Project Kit for practical demonstrations and academic submissions.

How to Choose the Right APFC Project Variant

Choosing the right automatic power factor correction project depends on your academic level, learning goals, and future scope. Students who are early in embedded systems or want faster conceptual clarity generally benefit from platforms that allow easier visualization and modification of control logic. On the other hand, learners aiming to strengthen low-level embedded fundamentals may prefer architectures that expose register-level control and deterministic timing behavior.

For curriculum-driven selection, diploma and polytechnic even B.tech and M.tech programs often emphasize foundational control concepts, while undergraduate and postgraduate programs focus on system understanding, optimization, and scalability. From a future-readiness perspective, selecting an APFC controller variant that allows extension into automation, monitoring, or intelligent control provides long-term learning value beyond a single semester or submission.

Academic and Practical Relevance

The automatic power factor correction project holds strong academic relevance because it directly maps to core subjects such as electrical machines, power systems, control systems, and industrial electronics. In laboratory examinations and viva sessions, this project helps students clearly explain reactive power, power factor improvement, and closed-loop control concepts using a practical reference system.

From a practical standpoint, power factor correction engineering projects closely resemble real industrial installations where energy efficiency and compliance with utility standards are critical. This makes APFC projects suitable not only for academic evaluation but also for demonstrations, applied research, and industry-oriented learning. As a result, APFC projects for students are widely accepted across institutions for final-year work, practical assessments, and interdisciplinary evaluations.

Future Extensions Across Platforms

While the core objective of an automatic power factor improvement system remains the same, the project offers significant scope for future expansion across platforms and technologies. Advanced learners can integrate communication interfaces for remote monitoring, data logging, or supervisory control, aligning the project with smart energy and automation trends.

At a higher level, power factor correction techniques can be enhanced using intelligent algorithms, adaptive control strategies, or predictive analysis for dynamic loads. Such extensions make the APFC project relevant for research-oriented work, industrial automation studies, and emerging smart grid applications, ensuring that the project family remains scalable and academically valuable for years.

Conclusion

The automatic power factor correction project is more than a single implementation—it is a structured project family that demonstrates how one engineering problem can be solved using multiple control technologies. By understanding the common concept once and comparing technology-specific implementations, learners gain both conceptual clarity and architectural insight.

This comparative approach makes APFC controller projects uniquely valuable for students, educators, and working engineers alike. Whether the goal is academic evaluation, practical learning, or future research readiness, this project family provides a clear, scalable, and technically sound foundation in modern power factor correction systems.

Visual FAQ – Automatic Power Factor Correction (APFC) Projects

Q1. What is an automatic power factor correction project and why is it important in engineering education?

A. An automatic power factor correction project demonstrates how reactive power in electrical systems is identified and compensated automatically to improve efficiency. It helps students understand real-world power system problems such as energy losses, voltage drops, and utility penalties. This project is widely used in engineering education because it directly connects theoretical power system concepts with practical control implementation. As a result, it forms a strong foundation for learning industrial power management techniques.

Q2. Are all APFC project variants based on the same working principle?

A. Yes, all automatic power factor correction projects operate on the same fundamental principle of measuring electrical parameters and compensating reactive power. The difference between variants lies in how the control logic is implemented and executed. While the core power factor correction techniques remain identical, the learning depth and system architecture vary across implementations. This makes the project ideal for comparative academic study.

Q3. How is an APFC project useful for exams, viva, and laboratory evaluations?

A. An APFC project for students is highly effective in exams and viva because it allows clear explanation of reactive power, power factor, and closed-loop control. Students can use the project to practically demonstrate how theory translates into system behavior. In laboratory evaluations, it helps assess understanding of measurement, decision-making logic, and system response. This makes it a preferred choice in electrical and electronics curricula.

Q4. Can the same APFC project concept be extended for advanced studies or research?

A. The automatic power factor improvement system concept is highly extensible and suitable for advanced academic work. Students can build upon the base project by integrating automation, monitoring, or intelligent control strategies. This scalability makes APFC projects relevant for final-year engineering work, postgraduate studies, and applied research. The concept remains valid even as control technologies evolve.

Q5. How should students decide which APFC project variant to choose?

A. Students should choose an APFC controller project based on their curriculum requirements and learning goals rather than hardware popularity. Beginners and concept-focused learners benefit from variants that emphasize clarity and system behavior. Those aiming for deeper embedded knowledge may prefer implementations that expose internal control logic. The key is selecting a variant that best supports conceptual understanding and academic evaluation.