Vehicle Automatic Headlight Control Project (High Beam Low Beam System)

₹9,800.00 Original price was: ₹9,800.00.₹8,800.00Current price is: ₹8,800.00.

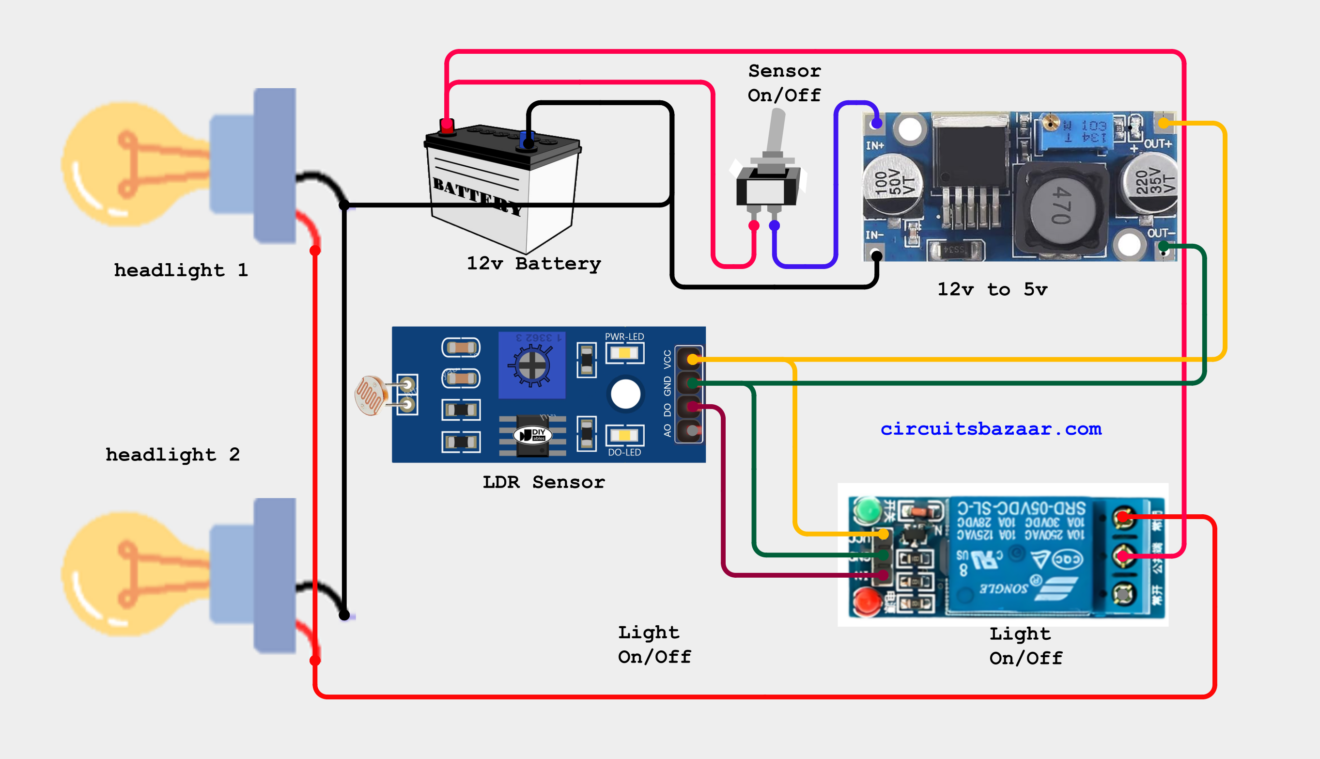

The Vehicle Automatic High Beam Low Beam Control project is a smart and practical solution designed to enhance road safety 🚗✨. Using an LDR sensor, LM358 comparator IC, relay system, and dual-headlight mechanism, this project automatically switches between high beam and low beam based on the intensity of incoming light. This prevents blinding oncoming traffic, reduces accidents, and eliminates unnecessary traffic fines.

The project is fully assembled, tested, and mounted on a strong wooden base. It includes a reliable 12V battery system, 5V regulated supply for sensors, up/down headlights, a powerful electromechanical relay, an ON/OFF master switch, and complete documentation (PPT + Report + Theory + Viva questions). Ideal for Diploma, B.Tech, M.Tech, Polytechnic, ITI, and school students. A perfect demonstration of real-world automotive automation. 🚀

500 in stock

The Vehicle Automatic High Beam Low Beam Control system is a modern engineering innovation designed to increase road safety and reduce the risk of accidents 🚗💡. It intelligently detects oncoming vehicles and adjusts the headlight beam automatically without requiring driver input. This prevents glare, ensures safe night driving, and helps drivers avoid unnecessary fines related to improper headlight usage.

With growing traffic and unsafe night-time driving habits, automatic beam control systems have become a valuable solution. This project uses simple yet effective components like LDR, LM358 comparator IC, relay, headlights, 12V battery, and a 5V regulated supply to achieve real-time automated switching.

🔍 Working Principle of the Project

The core idea of the Vehicle Automatic High Beam Low Beam Control project is based on light intensity detection. When an oncoming vehicle approaches, its headlights fall on the LDR (Light Dependent Resistor). The LDR senses this increased light and changes its resistance.

How the System Responds:

🟢 Low light conditions (night/dark):

LDR resistance rises

LM358 output activates relay

Relay switches headlights to High Beam

🔵 High light conditions (oncoming car):

LDR resistance drops

LM358 comparator reverses output

Relay shifts headlights to Low Beam

This smart operation ensures drivers get maximum visibility without causing inconvenience or danger to others.

⚙️ Components Used and Their Functions

📌 LDR (Light Dependent Resistor)

The LDR is the primary sensor. It detects the brightness level from opposite vehicles or street conditions. When less light hits the surface, resistance increases — triggering the high beam.

📌 LM358 Comparator IC

LM358 reads voltage differences between the LDR and the potentiometer’s reference value.

If voltage drops below threshold → switch beam down

If voltage rises → switch beam up

This IC ensures fast and accurate decision-making.

📌 Electromechanical Relay

The relay acts as a switch to control the dual-headlight system (high beam/low beam).

It handles the high current required by vehicle headlights while keeping control circuitry safe.

📌 Dual Headlights (Up/Down Beam System)

Two automotive headlights are connected to demonstrate real-world beam shifting — perfect for project exhibitions and vivas.

📌 12V & 5V Power Supply

12V battery 🔋 powers the headlights and relay

5V regulated module powers the sensor and LM358

📌 Additional Features

Master ON/OFF switch

Strong wooden mounting board

Optional buzzer/timer expansion

🎓 Academic Relevance & Learning Outcomes

This project is perfect for engineering students who want to understand:

Analog electronics

Sensor-based automation

Comparator circuits

Automotive safety systems

Relay-based power switching

Students can explain concepts of threshold detection, light variation, comparator logic, and load switching — scoring excellent marks in viva & evaluations. 🎯

🌟 Applications of the Project

Automatic headlight control in cars, trucks & buses

Highway safety enhancement

Anti-glare beam switching

Smart automotive electronics

Research, prototyping & student innovation

📦 What You Get in the Kit

✔ Fully assembled working project

✔ PPT for presentation

✔ Detailed report

✔ Circuit diagram & block diagram

✔ Viva questions & answers

✔ Future scope ideas

✔ Hindi & English demonstration videos

📈 Future Scope

IR sensor-based vehicle detection

Machine vision beam control

Microcontroller-based adaptive headlights

IoT-based road visibility monitoring

Cloud-based traffic assistance

📦 Read the Complete Blog of Vehicle Automatic Headlight Control Project

👉 Vehicle Automatic Headlight Control Blog

🔗 Internal Links

👉 Electrical Engineering Projects

👉 Electronics Engineering Projects

👉 Hardware Projects Without Coding

👉 Engineering Project Blog

🌐 External Resource Link (DoFollow)

👉 Road Safety and Vehicle Lighting Guidelines – Transport Authority

──────────────────────────────────────────

🎥 Project Demonstration Video

🎬 Hindi Demonstration 👇

🎬 English Demonstration 👇

🎬 Alternate Demo 👇

❓ Frequently Asked Questions

Q1. How does the Vehicle Automatic High Beam Low Beam Control system work in real-time?

The Vehicle Automatic High Beam Low Beam Control system works by continuously monitoring the light intensity using an LDR sensor 🌓. When an oncoming vehicle’s headlight falls on the LDR, the sensor detects the increased brightness and sends this signal to the LM358 comparator IC. The comparator evaluates the sensor voltage and triggers the relay accordingly.

When light is low, the system shifts to High Beam, giving the driver maximum visibility. When light is intense (like from an approaching car), it automatically switches to Low Beam to avoid glare. This fully automatic operation mimics real-world automotive headlight automation and significantly enhances road safety.

Q2. Is this project fully assembled, and can beginners use it easily?

Yes! This Vehicle Automatic High Beam Low Beam Control project is delivered fully assembled, tested, and ready to use. All the components — LDR sensor, LM358, relay, headlights, switches, and power systems — are already mounted neatly on a strong wooden board.

Even beginners, school students, or first-time engineering learners can use it easily because the project requires no programming and works entirely on analog electronics. The kit also includes a complete report, PPT, and demonstration videos to make learning simple and enjoyable.

Q3. What are the main components used in this project?

The project uses a carefully selected set of components to demonstrate real vehicle beam automation. These include an LDR sensor for light detection, LM358 comparator IC for decision-making, an electromechanical relay for switching the beams, dual headlights, a 12V battery, and a regulated 5V power module.

Additionally, it includes a high-quality ON/OFF switch, wiring, indicators, and a strong wooden board. These components together form a perfect practical learning model for automotive automation and sensor-based control systems.

Q4. Is this project suitable for final-year engineering students and competitions?

Absolutely! 🚀 This Vehicle Automatic High Beam Low Beam Control project is widely used by Diploma, B.Tech, M.Tech, Polytechnic, and ITI students for final-year submissions, lab demonstrations, competitions, and innovation events.

It offers excellent explanation value because it covers multiple core subjects — sensor technology, analog circuits, comparator logic, power electronics, relay control, and automotive safety systems. Students can score high during viva and practical evaluations because the project is logical, real-world, and easy to demonstrate.

Q5. Can the project be upgraded or customized to include modern features?

Yes, the system can be upgraded with smart enhancements like IR vehicle detection, microcontroller-based adaptive headlight control, IoT visibility monitoring, buzzer alerts, or cloud-based safety dashboards.

Students can also integrate it with other automotive modules (collision prevention, lane detection, fog-light automation) to create a more comprehensive smart vehicle system. The base design is extremely flexible, making upgrades simple and ideal for advanced research.

Related products

Arduino Based Projects

Anti-Sleep Alarm: Eye Blink Detection Project for Drowsiness Prevention #1

Electrical Engineering Projects

Underground Cable Fault distance Locator Electrical Project | Ver1

Electronics Engineering Projects

Driver Drowsiness and Alcohol Detection Vehicle Safety System Using Raspberry Pi Pico

Electronics Engineering Projects

🔥 Smart Army Robot for Metal & Landmine Detection 🔥 | Army Based Project

Electronics Engineering Projects

Best Selling Engineering Projects

Automatic Three Phase Changer Project Using Relay Logic | Electrical Engineering Project

8051 Microcontroller Based Projects

Electronics Engineering Projects