Four Quadrant Speed Control of DC Motor Engineering Project

₹15,800.00 Original price was: ₹15,800.00.₹14,000.00Current price is: ₹14,000.00.

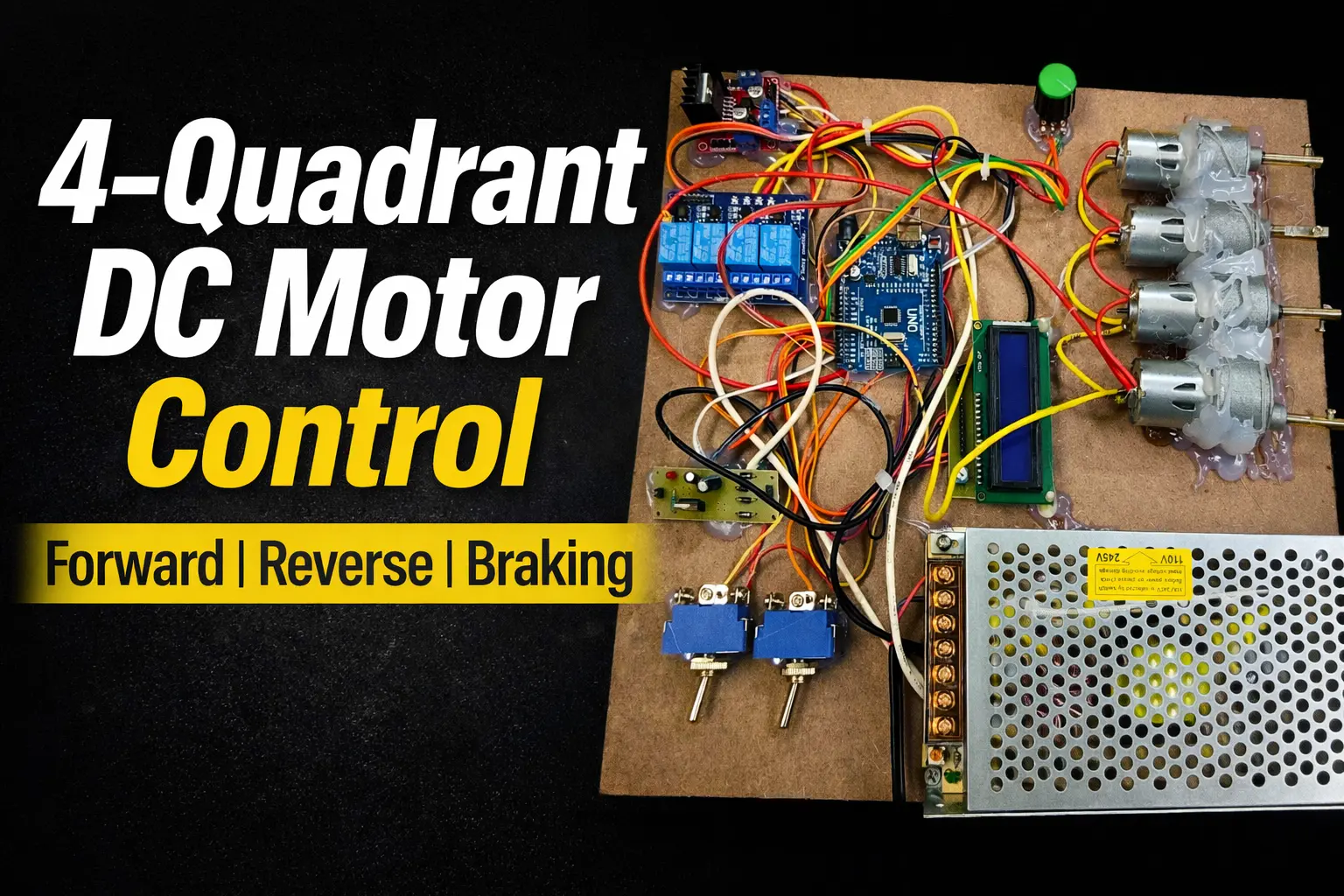

The four quadrant speed control of DC motor project is a practical and industry-relevant engineering solution designed to demonstrate complete motor drive control in real time. This fully assembled system allows controlled forward rotation, forward braking, reverse rotation, and reverse braking, all within a single setup.

Unlike basic motor projects, this model focuses on directional control, braking logic, and smooth speed variation using a heavy DC motor, making it ideal for Electrical and Electronics Engineering students. Speed is adjusted through a potentiometer, while direction and braking are handled through a relay-based control system. A live LCD display enhances understanding by showing operational status clearly.

This project is suitable for major projects, minor projects, lab demonstrations, and viva presentations, and comes with complete documentation, report, PPT, and video guidance.

👉 Download Four Quadrant DC Motor Project Synopsis and PPT (ZIP)

500 in stock

Introduction to Four Quadrant Speed Control of DC Motor

The four quadrant speed control of DC motor is an advanced motor drive concept widely used in industrial automation, electric vehicles, robotics, and motion control systems. In practical engineering education, students often study this concept theoretically, but rarely get the opportunity to understand its real-world implementation. This project bridges that gap by offering a fully functional, ready-to-use four quadrant DC motor speed control system.

In this project, a heavy DC motor is controlled in all four operating quadrants – forward motoring, forward braking, reverse motoring, and reverse braking. The speed of the motor is varied smoothly using a potentiometer, while directional and braking control is achieved using relays and a motor driver arrangement. The system is designed to be robust, safe, and easy to demonstrate during project evaluations.

What Does Four Quadrant Operation Mean?

In simple terms, four quadrant operation refers to the ability of a motor to operate in all combinations of direction and torque. This project clearly demonstrates:

Forward motion with speed control

Braking while moving forward

Reverse motion with speed control

Braking while moving in reverse

This makes the four quadrant speed control of DC motor project significantly more advanced than ordinary forward–reverse motor control circuits.

Core Components Used in the Project 🧠

This project uses carefully selected hardware components to ensure stable performance and easy understanding:

Heavy-duty DC motor for realistic load behavior

Motor driver module suitable for high-current operation

Relay module for direction and braking logic

Potentiometer for analog speed control

Arduino-based control unit

16×2 LCD display for live feedback

Regulated power supply with proper isolation

All components are neatly mounted and wired, making the project visually clear and ideal for demonstrations.

Want to understand how this project works in detail?

We have explained the complete working, circuit, and applications in a dedicated blog article.

Working Principle Explained Simply 🗣️

The working of the four quadrant speed control of DC motor project is based on coordinated control of speed, direction, and braking:

The potentiometer provides an analog input that controls motor speed.

The controller converts this input into a control signal for the motor driver.

Relays are used to switch motor polarity, enabling forward and reverse rotation.

Controlled braking is achieved by switching the motor terminals appropriately during motion.

The LCD continuously displays speed and system status for better understanding.

Because of this structured control approach, students can clearly visualize how industrial DC drives operate.

Why This Project Is Academically Strong 🚀

This project is not just about running a motor; it focuses on drive control logic, which is a key topic in electrical engineering curricula. It helps students understand:

DC motor characteristics

Directional control techniques

Braking methods in motor drives

Real-world implementation of four quadrant DC drives

The four quadrant speed control of DC motor project is often appreciated by evaluators because it demonstrates both theoretical knowledge and practical execution.

Applications of Four Quadrant DC Motor Control 👌

This project directly relates to real-world applications such as:

Electric vehicles with regenerative braking concepts

Industrial conveyors and cranes

Elevators and hoists

Robotics and automated guided vehicles

Machine tools requiring precise motion control

These applications make this project highly relevant for students aiming for industry-oriented learning.

Who Can Use This Project?

This project is suitable for a wide audience:

B.Tech and M.Tech students

Diploma and Polytechnic students

ITI trainees

School-level science exhibitions

Hobbyists and researchers

Since it is delivered fully assembled with documentation, no complex setup is required.

What You Will Receive with the Project 📦

Fully assembled and tested hardware

Detailed project report (PDF)

PPT for viva and presentation

Theory and explanation notes

Working and demonstration videos

Guidance for future scope and upgrades

🎥 Project Demonstration Video

🎬 Hindi Demonstration 👇

🔗 Internal Resource Links

❓ Frequently Asked Questions

❓ What makes this Four Quadrant Speed Control of DC Motor project different from normal DC motor projects?

Answer:

Unlike basic DC motor projects that only demonstrate speed control or direction change, this four quadrant speed control of DC motor project showcases complete industrial motor drive behavior. It covers forward motoring, forward braking, reverse motoring, and reverse braking in a single system. This makes it highly valuable for engineering evaluations, viva explanations, and understanding real-world motor control applications used in industries.

❓ Is this project suitable for major or minor engineering project submission?

Answer:

Yes, this project is highly suitable for minor projects, major projects, and final-year engineering submissions. It demonstrates advanced concepts like braking logic, directional control, and speed regulation, which are well-aligned with Electrical and Electronics Engineering curricula. The provided report, PPT, and videos help students confidently explain the project during evaluations.

❓ Does the project support heavy DC motors or only small lab motors?

Answer:

This four quadrant speed control of DC motor project is designed to work with heavy DC motors, not just small demonstration motors. The use of proper motor drivers and relay-based control ensures reliable handling of higher current requirements, making the project closer to real industrial motor drive systems.

❓ Will I receive documentation and learning material along with the hardware?

Answer:

Absolutely. Along with the fully assembled hardware, you will receive a detailed project report, presentation slides (PPT), theory notes, working explanation, and demonstration videos. These resources are especially useful for viva preparation, seminars, and understanding the logic behind four quadrant motor control.

❓ Can this four quadrant DC motor project be upgraded or extended further?

Answer:

Yes, this project offers excellent scope for future upgrades. Students can extend it by adding regenerative braking concepts, IoT-based monitoring, current sensing, closed-loop speed control, or industrial-grade controllers. Such enhancements make it suitable for research work and advanced academic exploration.

📚 References / Further Reading

Related products

Electronics Engineering Projects

Wireless Landmine & Metal Detection Robot – Smart Defense Project for Students

Arduino Based Projects

Border Intrusion Detection System Using Arduino and GSM Wireless Network – Innovative Army Project

Electrical Engineering Projects

Vehicle Automatic Headlight Control Project (High Beam Low Beam System)

Best Selling Engineering Projects

Solar Inverter Electrical Engineering Project – Buy Ready-Made Model

Electronics Engineering Projects

Vehicle Accident Alert System using Magnetic Sensor, Arduino and GSM Modem.

Electronics Engineering Projects

Arduino Based Projects

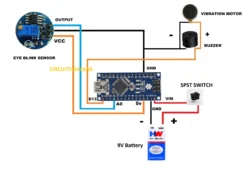

Anti-Sleep Alarm: Eye Blink Detection Project for Drowsiness Prevention #1

Electronics Engineering Projects