8051 Projects Blogs

Automatic Wireless Controlled Smart Floor Cleaning Robot – Ultimate Engineering Project Guide

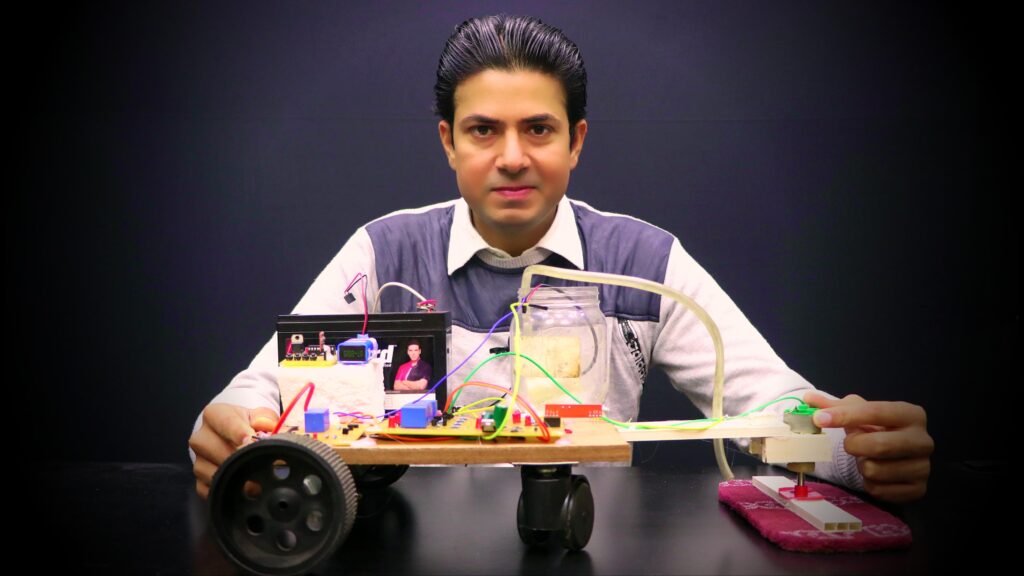

In recent years, there has been an increased focus on robotics and automation in engineering projects. One such innovation is the Automatic Wireless Controlled Smart Floor Cleaning Robot, a unique project designed to make floor cleaning efficient, intelligent, and remote-controlled. Ideal for engineering students, this project combines robotics, wireless control, and automation, offering a valuable learning experience in building and coding with a practical application. This blog will guide you through the components, working principles, advantages, applications, and future scope of this exciting project.

Introduction

The Automatic Wireless Controlled Smart Floor Cleaning Robot is an innovative engineering project designed to teach students how wireless robotics, embedded systems, and automation can work together to create a functional cleaning robot. This Automatic Wireless Controlled Smart Floor Cleaning Robot uses an 8051 microcontroller, RF wireless control, DC motors, and a water pump to deliver a fully operational floor-cleaning system. It is ideal for engineering students who want hands-on experience in robotics, automation, wireless communication, and microcontroller interfacing. 💡🤖

Project Objective & Overview

The main objective of this project is to create a wireless-operated floor-cleaning robot that can be controlled using RF signals. The robot moves in all four directions, sprays water, and rotates a front-mounted mopper to clean surfaces. It teaches students real-world concepts like:

👉 Microcontroller-based automation

👉 RF communication (433 MHz)

👉 Relay-driven motor control

👉 Pump activation and power circuitry

👉 Robotics chassis and free-wheel movement

This project is suitable for school, Diploma, B.Tech, M.Tech, ITI, and hobby-level learners.

📦 Related Products / Resources

👉 Automatic Wireless Controlled Smart Floor Cleaning Robotic Project

Video Demonstration :-

Components Used

In this project, we use several key components to achieve the desired functionality of a wireless-controlled floor cleaning robot. Below are the primary components and their functions:

- 8051 Microcontroller

The 8051 microcontroller serves as the central control unit of the robot. It interprets inputs, sends signals to components like the DC motors and water pump, and allows wireless control through programmed commands. - DC Geared Motors

Two DC geared motors power the wheels of the robot, allowing it to move across the floor efficiently. These motors are controlled by the microcontroller, enabling forward, backward, left, and right movements based on input signals. - Submersible 5V Water Pump

A small, efficient water pump that sprays water onto the floor during the cleaning process, the pump is activated by a relay connected to the microcontroller, allowing precise control over water release. - Wireless RF Module (433 MHz)

The RF module provides wireless communication, allowing the robot to be controlled remotely. This feature enables the robot to clean areas without the need for manual supervision, enhancing the automation aspect of the project. - Relay Modules

Relays are used to control the motors and pump, serving as an intermediary switch controlled by the microcontroller to manage the flow of power to various components. - Power Supply

A stable power supply is essential for consistent operation, especially for the motors and pump, which require significant power for extended use.

📦 Related Products / Resources

👉 Automatic Wireless Controlled Smart Floor Cleaning Robotic Project

Working Principle of the Smart Floor Cleaning Robot

The Automatic Wireless Controlled Smart Floor Cleaning Robot operates through a combination of programmed instructions and wireless control signals. Below is a breakdown of its working mechanism:

- Receiving Input Signals

The RF module receives wireless signals that are interpreted by the 8051 microcontroller. These signals can command the robot to move in different directions, spray water, or stop. - Control Mechanism

The microcontroller uses relays to control the DC motors and the water pump based on the signals received. By turning the relays on or off, the microcontroller can initiate or stop the movement of the robot or the release of water. - Movement and Navigation

The two DC motors allow the robot to move in forward, backward, left, or right directions. Depending on the signal received, the microcontroller adjusts the motor direction and speed for precise control. - Cleaning Mechanism

When the robot moves across the floor, the 5V water pump releases water for cleaning. The water is then spread evenly by the movement of the robot, allowing for efficient floor mopping without manual intervention.

Code:-

#include <reg51.h>

sbit M1F = P1^0;

sbit M1B = P1^1;

sbit M2F = P1^2;

sbit M2B = P1^3;

sbit PUMP = P1^4;

void forward() {

M1F = 1; M1B = 0;

M2F = 1; M2B = 0;

}

void backward() {

M1F = 0; M1B = 1;

M2F = 0; M2B = 1;

}

void left() {

M1F = 0; M1B = 1;

M2F = 1; M2B = 0;

}

void right() {

M1F = 1; M1B = 0;

M2F = 0; M2B = 1;

}

void pump_on() {

PUMP = 1;

}

void pump_off() {

PUMP = 0;

}

void main() {

while(1) {

switch(P2) {

case 0x01: forward(); break;

case 0x02: backward(); break;

case 0x04: left(); break;

case 0x08: right(); break;

case 0x10: pump_on(); break;

default: pump_off();

}

}

}

How the Project Works (Step-by-Step Explanation)

Let’s break down how the robot operates in simple, clear steps. ⚙️🔧

1. RF Transmitter Sends Wireless Commands

The RF handheld remote contains the HT12E encoder, which converts user button-presses into digital data and transmits them via a 433 MHz RF module.

2. RF Receiver Captures the Signals

The robot has an HT12D decoder module that receives the RF data and converts it to 4-bit output, which is:

- Displayed on LEDs

- Sent to the 8051 microcontroller

These LEDs help students visually understand the received command.

3. Microcontroller Processes the 4-bit Data

The 8051 microcontroller reads the received wireless data and executes actions like:

- Move forward

- Move backward

- Turn left

- Turn right

- Activate water pump

4. Relay Control System

A Darlington transistor pair (BC547) is used for relay activation.

The relay bank includes:

- 4 relays for motor direction control

- 1 separate relay for water pump control

5. Movement System

Two DC motors create the movement, and a front thruster wheel allows smooth rotation. The relay combinations reverse motor polarity for directional motion.

6. Cleaning Mechanism

The high-torque DC mopper motor rotates continuously.

The water pump sprays water onto the mopper area to clean dust effectively.

7. Power Supply

- 12V high-current battery for motors

- 7805 voltage regulator for 5V logic supply

- Rectifier + filter capacitors ensure stable operation

🤖 In summary: Wireless command → RF receiver → 8051 logic → Relay activation → Motor/Pump operation → Floor cleaning.

📦 Related Products / Resources

👉 Buy Fully Assembled Automatic Wireless Controlled Smart Floor Cleaning Robot

Applications of the Automatic Wireless Controlled Smart Floor Cleaning Robot

The Automatic Wireless Controlled Smart Floor Cleaning Robot has numerous practical applications that make it a valuable addition to various settings. Here are some prominent applications:

- Household Cleaning

This robot can be used for automatic cleaning in homes, reducing the manual effort required for daily floor mopping and enhancing cleaning efficiency. - Commercial Spaces

The robot is ideal for office spaces, malls, and showrooms where consistent cleanliness is essential. It can be programmed to operate during off-peak hours, ensuring clean floors without disrupting normal operations. - Hospitals and Clinics

With automated control, this cleaning robot is highly beneficial in healthcare settings, where cleanliness is crucial for patient safety. By reducing manual cleaning, it also minimizes human contact with potentially contaminated surfaces. - Educational Use

Engineering and robotics students can use this project to gain hands-on experience with microcontrollers, motor control, and wireless communication. It’s an excellent project for learning automation principles and hardware programming. - Industry

This robot can be used in small industrial settings to maintain cleanliness in areas that may be challenging for humans to clean consistently. Automated floor cleaning contributes to a safer working environment.

Advantages and Disadvantages

Advantages

- Automation

This project offers a hands-free approach to cleaning, making it convenient and efficient for users, especially in larger areas where manual cleaning is time-consuming. - Cost-Effective

Built with readily available components like the 8051 microcontroller and DC motors, this robot is a cost-effective solution compared to commercially available robotic cleaners. - Wireless Control

The integration of a 433 MHz RF module enables wireless control, allowing users to operate the robot remotely, making it user-friendly and versatile. - Educational Value

This project provides engineering students with practical experience in automation, electronics, and programming, all crucial skills in today’s job market.

Disadvantages

- Limited Battery Life

The robot may require frequent charging or a robust power supply if used for extended periods, particularly in large spaces. - Limited Cleaning Capability

Unlike commercial robotic vacuum cleaners, this DIY model may lack advanced sensors or a strong suction mechanism, limiting it to basic floor mopping tasks. - Manual Refilling of Water

The submersible water pump requires regular refilling, which might be inconvenient in larger cleaning spaces.

Future Scope

The Automatic Wireless Controlled Smart Floor Cleaning Robot has significant potential for further enhancement and scalability. Here are some possible upgrades:

- Integration of Sensors

Adding ultrasonic or infrared sensors can enable obstacle detection, making the robot autonomous and more efficient in navigation. - Advanced Battery and Charging Solutions

Future versions can incorporate a larger-capacity battery or a self-charging mechanism to extend the robot’s operating time. - IoT Connectivity

Integrating Internet of Things (IoT) technology could allow users to control the robot via a smartphone app, enabling scheduled cleaning and remote monitoring. - Water Level Indicator

A water level sensor could be added to alert users when the water reservoir needs refilling, enhancing user convenience. - Enhanced Cleaning Mechanism

Incorporating a vacuum motor along with the water spray could allow the robot to perform both sweeping and mopping functions, making it a comprehensive cleaning solution.

Conclusion

The Automatic Wireless Controlled Smart Floor Cleaning Robot is a remarkable project that merges engineering principles with practical application. Built with components like the 8051 microcontroller, DC motors, and an RF module, this project provides engineering students with an opportunity to explore automation and wireless control in robotics. Its applications in households, industries, and healthcare make it versatile, and its potential for future enhancements presents exciting possibilities in robotics. This project not only demonstrates the power of automation in solving everyday problems but also serves as an invaluable learning tool for anyone interested in robotics and engineering.

📦 Related Products / Resources

👉 Buy Fully Assembled Automatic Wireless Controlled Smart Floor Cleaning Robot

🔗 Internal Resource Links

👉 Electrical Engineering Projects

👉 Hardware Projects Without Coding

👉 Electronics Engineering Projects

👉 Best Seller Engineering Projects

❓ Frequently Asked Questions

1. How does the Automatic Wireless Controlled Smart Floor Cleaning Robot actually work?

The Automatic Wireless Controlled Smart Floor Cleaning Robot works by receiving wireless RF signals that are decoded using the HT12D module and then processed by the 8051 microcontroller. ⚙️📡 The microcontroller activates specific relays that drive the motors for directional movement and operate the pump for wet cleaning. As the robot moves, the front mopper motor rotates continuously to wipe the floor while the pump sprays water for effective cleaning.

2. Is this project suitable for engineering final-year submissions?

Yes, this project is excellent for engineering final-year submissions because it includes wireless communication, motor control, pump operation, and embedded logic. 🎓🤖 It is fully assembled, easy to demonstrate, and teaches important topics like RF control, microcontroller interfacing, and relay-based automation. Students can confidently present it in Viva, exhibitions, and competitions.

3. What components are essential in the Automatic Wireless Controlled Smart Floor Cleaning Robot?

This robot uses key components such as an 8051 microcontroller, HT12E/HT12D RF pair, high-torque mopper motor, two DC drive motors, 5V water pump, relays, 7805 regulator, and a 12V battery. 🔋⚙️ These components work together to enable wireless movement, water spraying, and floor mopping. Every component plays a specific role in controlling direction, activation, or power regulation.

4. Can this project be upgraded or customized for advanced applications?

Absolutely! Students can upgrade this project by adding ultrasonic sensors for obstacle detection, Bluetooth/WiFi for IoT control, or a camera for surveillance-based robotic cleaning. 🚀🔮 You can also integrate automatic charging, Android app control, or vacuum suction to make it a hybrid cleaning robot. The design is flexible and supports multiple enhancements.

H3: 5. Is this project beginner-friendly for students learning embedded systems?

Yes! This is a beginner-friendly project because it uses basic relay logic, RF remote control, and simple microcontroller programming. 🧠👌 Students learn wireless communication, direction control, and power electronics in a practical way. Even those new to embedded systems can understand and implement the concepts easily.

🌐 External Reference

👉 ScienceDirect – Robotics Concepts

📚 References / Further Reading

👉 Circuits Bazaar Engineering Blogs

👉 Electronics For You – Robotics Articles